A Practical Lead Time Guide for Brands and Product Teams

For many brand owners and product teams, product development feels almost complete — formulations are approved, suppliers are lined up, and marketing plans are ready.

Then packaging becomes the bottleneck.

Launch dates slip.

Retail windows are missed.

Promotions are postponed.

In our experience working with international food, pet food, coffee and supplement brands, packaging is rarely the slowest step by design — but it is often the most underestimated one.

This article explains why custom flexible packaging so often delays product launches, what actually causes lead time overruns, and how brands can regain control of packaging timelines without rushing production or increasing risk.

The Problem: Packaging Is Ready Last — and Finishes Last

A familiar scenario:

- Product formulation is finalized

- Regulatory approvals are completed

- Sales and marketing timelines are confirmed

Packaging is treated as a downstream task. This issue is especially common for brands launching new products in stand-up pouches with multiple SKUs and tight timelines.

Only when artwork is submitted does the team realize:

- Production slots are limited

- Artwork needs multiple revisions

- Shipping timelines are longer than expected

By then, packaging is no longer supporting the launch — it is defining it.

The Root Cause: Flexible Packaging Lead Time Is Cumulative, Not Linear

One of the biggest misconceptions is thinking packaging lead time equals printing time.

In reality, custom flexible packaging lead time is cumulative — each stage depends on the previous one.

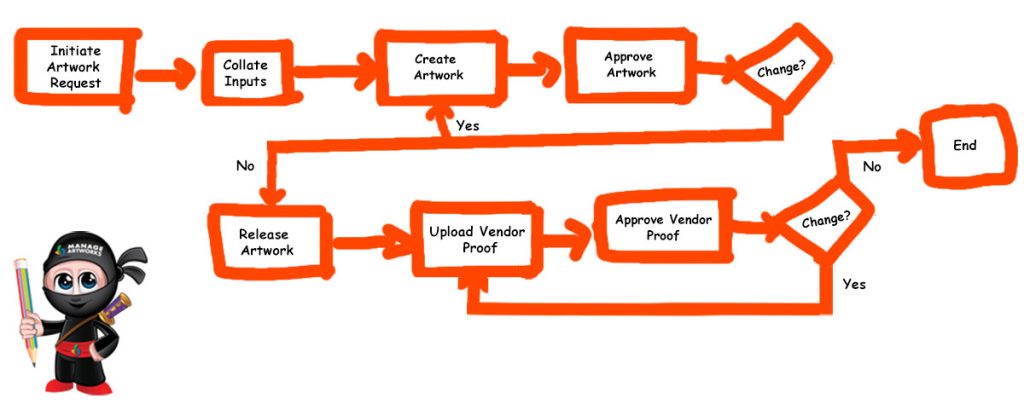

1. Artwork Approval Is the First Critical Path

Artwork is not a formality.

It is the entry point into production.

Delays often occur because:

- Artwork looks approved visually but is not print-ready

- Multiple stakeholders request late changes

- Print constraints are discovered only after submission

We frequently see projects where artwork approval alone takes longer than printing itself, pushing production slots out by weeks.

2. Production Scheduling Is Capacity-Driven

Flexible packaging production is not “on demand.”

- Printing machines run on planned schedules

- Missed slots are rarely recoverable without expediting

- Late confirmation often means waiting for the next available window

From a manufacturing perspective, artwork delays almost always translate directly into production delays — not because factories are slow, but because printing capacity and production schedules are fixed.

As volumes grow, some brands eventually move from pouches to roll stock packaging to improve production efficiency and scheduling stability.

3. Material Processing and Curing Time Are Often Overlooked

After printing, flexible packaging still requires:

- Lamination

- Adhesive curing

- Slitting and pouch conversion

These steps cannot be rushed without quality risk.

Brands that underestimate these stages often discover too late that:

“Printing finished” does not mean “packaging is ready to ship.”

4. Logistics Adds Non-Negotiable Time

Even when production finishes on schedule:

- Export handling

- Sea or air freight

- Customs clearance

add fixed time to the process.

Late production decisions usually force:

Higher logistics cost

Expedited freight

Split shipments

The Solution: How Brands Regain Control of Packaging Lead Time

Successful brands do not try to make packaging faster.

They make it earlier.

Step 1: Treat Packaging as a Launch-Critical Workstream

Packaging should start in parallel with:

- Product finalization

- Regulatory review

- Marketing planning

Not after.

Brands that bring packaging into the timeline earlier gain buffer — without rushing.

Step 2: Lock Artwork Earlier Than Feels Comfortable

Waiting for “perfect” artwork often causes more delay than benefit.

Best practice:

- Finalize structural elements early

- Freeze core design components

- Limit late-stage revision cycles

In practice, projects with clear artwork cut-off dates consistently launch on time — even if minor visual tweaks are deferred to future runs.

Step 3: Align Launch Dates with Production Reality

Rather than asking:

“Can you make this faster?”

Ask:

“What launch date aligns with your next stable production slot?”

This shift alone:

Lowers stress across teams

Reduces expediting risk

Improves quality consistency

A Practical Case Example

A nutraceutical brand planned a product launch tied to a marketing campaign.

Originally:

- Artwork approval was scheduled after formulation sign-off

- Packaging was expected to “fit into” the timeline

After revising the approach:

- Artwork was finalized earlier

- Production slots were booked in advance

- Shipping was aligned with launch dates

Result:

The product launched on schedule — without rush fees or production compromises.

Key Timeline Insights Brand Teams Should Know

- Artwork approval often consumes 30–40% of total packaging lead time

- Missed production slots are the most common cause of launch delays

- Packaging timelines are hardest to compress at the end, not the beginning

Final Takeaway: Launch Delays Are Rarely Caused by Printing

Custom flexible packaging delays are not a production failure.

They are a planning sequence issue.

Brands that:

- Start packaging earlier

- Respect artwork as a production input

- Align timelines with manufacturing reality

consistently launch on time — without sacrificing quality or cost control.

Frequently Asked Questions (FAQ)

1) How long does custom flexible packaging usually take from artwork to delivery?

Lead time varies, but it typically includes artwork approval, printing, lamination, curing, conversion, and shipping. Each step adds time that cannot be skipped.

2) Why does artwork approval delay packaging so often?

Because artwork must meet technical print requirements. Visual approval alone is not sufficient for production readiness.

3) Can packaging production be rushed safely?

Some steps can be expedited, but rushing lamination, curing, or conversion increases quality risk and cost.

4) When should brands start packaging development?

Ideally in parallel with product development and regulatory review, not after everything else is finished.

5) What is the most common mistake brands make with packaging timelines?

Treating packaging as a downstream task instead of a launch-critical workstream.