A Practical Cost Control Guide for Brands and Procurement Teams

When sourcing custom flexible packaging, many brand owners, product teams, and procurement teams naturally focus on one number: the unit price per pouch.

At first glance, this makes perfect sense. Packaging is often one of the largest variable costs for food, café, beverage, pet food, and supplement brands. A lower pouch price appears to mean healthier margins.

Yet in real projects, experienced teams across different brand stages repeatedly encounter the same frustration:

- The pouch itself is rarely expensive.

- Everything around it is.

In our experience working with international brands and procurement teams across food, pet food, supplement and other categories, we see this pattern repeatedly: the initial pouch price is approved quickly, while the real cost impact only becomes visible once production and artwork workflows begin.

This article explains why “low-price” custom flexible packaging often becomes expensive later, what causes these hidden costs, and how professional brand teams control total packaging spend through better artwork workflow and production planning.

The Problem: Why Initial Quotes Rarely Reflect the Final Cost

A typical scenario looks like this:

- You receive a competitive quotation for a custom printed pouch

- The price is approved internally

- Artwork is submitted and production planning begins

Then additional costs appear:

- Printing plates or cylinders

- Artwork revisions and file corrections

- Rush production fees

- Split shipments and higher freight costs

By the time the packaging arrives at your warehouse, the total landed cost is significantly higher than expected.

This issue is rarely caused by dishonest suppliers. It is caused by how flexible packaging is manufactured.

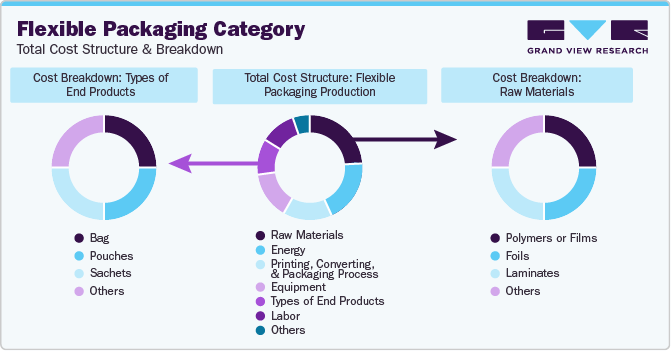

The Root Cause: Flexible Packaging Is a Process-Based Cost System

Unlike rigid packaging or stock bags, custom flexible packaging is not a simple “per-piece” product.

It is a process-driven manufacturing system, where cost is influenced by multiple connected decisions.

1. Artwork Workflow

Artwork is not just visual design. In flexible packaging, artwork directly determines:

- Ink coverage and color separation

- Cylinder layout and repeat length

- Registration tolerance and trapping

Poorly prepared artwork almost always leads to rework, delays, and additional charges.

We frequently receive artwork files that look visually approved but are not production-ready, especially for gravure printing, where even minor layout or color changes can require new cylinders and reset production schedules.

2. Printing Technology

Different order volumes require different printing technologies:

- Digital printing for small runs, test markets, and frequent design updates

- Gravure or flexographic printing for stable, high-volume programs

Choosing the wrong method creates unnecessary fixed costs.

In several projects we reviewed last year, brands selected gravure printing for volumes that were still evolving, which later forced costly artwork changes and plate write-offs that could have been avoided with a digital-first approach.

3. Production Organization

How your order is produced has a major cost impact:

- Dedicated production runs vs. shared production

- Fragmented SKUs vs. consolidated artwork

- Single shipment vs. split deliveries

Each decision affects efficiency and cost.

From a manufacturing perspective, fragmented SKUs and late-stage design changes are two of the most common reasons we see production efficiency drop and unit costs rise unexpectedly.

4. Logistics and Timing

Late artwork approvals often trigger:

- Missed production slots

- Expedited manufacturing

- Air freight instead of sea freight

These costs rarely appear in the initial quote but can significantly affect the final invoice.

The Solution: How Professional Brands Control Total Packaging Cost

Experienced brand teams do not ask:

“How cheap is this pouch?”

They ask:

“How predictable is the total cost?”

Here is how they achieve that.

Step 1: Treat Artwork as a Production Tool, Not Decoration

One of the most underestimated cost drivers is artwork rework.

Professional brands ensure artwork is:

- Print-ready before quotation

- Designed within realistic ink coverage limits

- Compatible with the selected printing method

This reduces:

- File correction fees

- Plate or cylinder changes

- Production delays

A well-managed artwork workflow alone can reduce total packaging cost by 10–15%.

In practice, projects with clear artwork guidelines and limited revision cycles consistently move faster and generate fewer disputes during production, especially when multiple stakeholders are involved in approvals.

Step 2: Match Printing Method to Volume and Product Lifecycle

Low unit prices are meaningless if the production method is mismatched.

Best practice:

- Use digital printing for early-stage or fast-changing products

- Transition to gravure or flexo printing only when volumes are stable and predictable

This approach avoids unnecessary fixed costs and write-offs.

Step 3: Evaluate Cost as “Total Landed Cost,” Not Unit Price

Professional brand teams evaluate:

- Pouch unit price

- Plate or cylinder cost (and amortization method)

- Expected artwork revision cycles

- Freight mode and delivery timing

- Risk of expediting

This creates cost predictability, which is far more valuable than a low headline price.

A Practical Case Example

A functional nutrition brand was sourcing stand-up pouches for multiple SKUs.

Originally:

- Each SKU had a separate artwork file

- Production was scheduled individually

- Artwork revisions averaged 6–7 rounds per SKU

After restructuring the workflow:

- Artwork templates were standardized

- Production was consolidated

- Artwork revisions dropped to 2 rounds

Result:

Without changing materials or suppliers, total packaging spend dropped by 18% within one year.

Based on our day-to-day project reviews, the most successful buyers are not those who negotiate the lowest pouch price, but those who invest time upfront in artwork clarity and production alignment.

Key Data Points Brand Teams Should Know

- Over 30–40% of flexible packaging cost overruns come from non-unit-price factors

- More than 60% of artwork files require modification before printing

- Early artwork and production alignment can reduce total cost by 10–20%

Final Takeaway: Cost Control Starts Before the Quote

Custom flexible packaging becomes expensive only when the process is unmanaged.

The most successful brand teams:

- Control artwork workflow early

- Align printing technology with volume and design stability

- Evaluate total landed cost instead of unit price

When packaging is treated as a system rather than a commodity, costs become predictable — and margins remain protected.

Frequently Asked Questions (FAQ)

1) Why does custom flexible packaging have extra fees beyond the pouch unit price?

Custom flexible packaging is process-based. Costs often include prepress setup, printing plates or cylinders, artwork revisions, production scheduling, and freight.

2) What are the most common hidden costs brands miss?

Typical surprises include cylinder costs, artwork rework, rush production fees, split shipments, and import duties depending on shipping terms.

3) How can brands reduce total landed cost without changing materials?

Most savings come from workflow optimization: freezing artwork earlier, reducing revisions, consolidating SKUs, and matching printing technology to real volumes.

4) Does digital printing always cost more than gravure or flexo?

No. Digital printing can be more cost-effective for short runs and frequent design changes because it avoids cylinder costs and reduces risk.

5) What makes artwork print-ready for flexible packaging?

Print-ready artwork includes correct dielines and bleed, proper color setup, font handling, trapping/overprint settings, and realistic ink coverage.